With the vast array of types of sewing machines available today, from basic mechanical to fully computerized, it can be daunting to find the right one for your needs. In this comprehensive guide, we will explore the main sewing machine types for home and industrial use, so you can determine which is best suited for your goals, skills, and projects. Whether you are new to sewing and need a starter machine or have years of experience and need specialty machines, reading about the various types of sewing machines will ensure you make the perfect choice.

Table of Contents

What’s the Difference Between a Domestic and an Industrial Sewing Machine?

Before diving into the specific types covered later in this guide, let’s first tackle the fundamental differences between domestic and industrial sewing machines.

Domestic sewing machines

Domestic sewing machines are designed for personal home use. They work best for most home sewing projects, such as making minor clothing repairs, crafting personalized home decor items, hemming pants, or sewing on buttons.

Key features of domestic sewing machines include:

- Simpler operation using basic dials, buttons, and levers. Many newer computerized models feature intuitive LCD touch screens.

- Lightweight, portable construction is perfect for use in a home craft room.

- Less expensive price point, usually under $500. Even basic mechanical models cost under $150.

- Basic built-in stitches and functions like straight, zigzag, and stretch. Higher-end computerized machines offer hundreds of stitch options.

- There are limitations in sewing very heavy fabrics like denim or canvas or handling the large sewing volumes required in manufacturing. Domestic machines work best for lighter fabrics like cotton, linen, and general home sewing use.

Industrial sewing machines

Industrial sewing machines represent the heavy-duty workhorses used in factories, tailor shops, upholstery businesses, and anywhere requiring mass quantities of sewing and heavy-duty projects.

Key features of industrial sewing machines include:

- Ideal for large-scale production lines, garment factories, upholstery shops, and other commercial and manufacturing sewing needs.

- Robust, durable construction from cast iron and all-metal internal components allows continuous high-speed sewing.

- Specialized stitches and automated features are designed to tackle heavy-duty tasks like binding thick upholstery.

- Much faster sewing speeds—some over 5,000 stitches per minute! Makes quick work of long seams.

- Higher-cost machines range from $2,000 to $5,000+. Significant investment is necessary for sewists and businesses with high volume or heavyweight sewing demands.

- Complex operation requiring trained professional operators. Most computer and automated controls optimize completing specialized stitch types required in manufacturing.

- Bulky, heavy machines are not practical for transport. Permanent installation works best.

- Not suitable for very delicate fabrics that require careful handling at slower speeds.

Choosing Between Domestic and Industrial

When deciding between a domestic or industrial sewing machine, consider factors like your skill level, the types of projects and fabrics you’ll work with, and your budget.

Beginners often find domestic machines easier to use for general home sewing. As your skills grow and projects become more complex, you can upgrade to more heavy-duty domestic options or invest in an industrial machine if you pursue sewing professionally or start a manufacturing business.

Types of Sewing Machines (Domestic)

Within the broad category of domestic sewing machines, there are several types optimized for different functions and sewing needs.

Mechanical Sewing Machine

Mechanical sewing machines operate via an electric motor rather than manual power. They typically offer basic straight stitching and zigzag. Select adjustable stitch width and length settings to provide some versatility.

Mechanicals represent affordable, intuitive machines great for straightforward projects requiring basic stitches. Limitations include fewer built-in stitches and functions compared to computerized options. But mechanical reliability makes them workhorse sewing machines that can last decades.

Electronic Sewing Machine

Electronic sewing machines introduced more digitally controlled functionality while still using analog dials and buttons for adjustments. More varied stitch options, needle positioning, and speed controls provide additional flexibility.

Mid-range electronic machines nicely balance ease of use with greater capabilities for creative sewing. They make an excellent choice for intermediate sewers. The electronics make them less easily repairable than basic mechanicals.

Computerized Sewing Machine

Modern computerized sewing machines contain full digital computers with LCD screens and touchpad controls. This allows programming hundreds of built-in stitches, automatic functions like thread trimming, and simple selections through menu navigation.

Computerized sewing machines provide the ultimate convenience for sewers of any skill level. Their innovative features and intuitive operation make tricky techniques like buttonholes completely foolproof, even for beginners. Higher costs can make affordability a limitation for some.

Within domestic computerized machines, there are also specialized types designed for techniques like embroidery, quilting, garment construction, and more. We will explore the capabilities of these next.

Specialized Domestic Sewing Machines

In addition to the general-use domestic machines above, there are specialty machines tailored to specific sewing techniques.

Mini/Portable Sewing Machine

As the name suggests, these ultra-compact machines provide maximum portability and ease of storage. Mini machines work well for sewing on the go, basic repairs, and as a secondary travel machine. Limitations come with fewer built-in stitches and smaller throat sizes that limit fabric capacity.

Heavy-Duty Sewing Machine

Heavy-duty domestic sewing machines are designed to handle thicker fabrics like denim, canvas, and multiple layers easily. Sturdier construction, more powerful motors, and specialty needles allow them to sew materials that other domestic machines can’t. They are great for frequent quilting, home décor projects, or apparel sewing with heavy fabrics.

Quilting Machine (long arm quilting machine)

Specialized quilting machines feature an extra-long throat space to accommodate bulky, large quilts rolled under the arm for maneuverability. Some models mount on wide-frame tables. Many include stitch regulators, knee lifts, and other ergonomic features for marathon quilting sessions.

Embroidery Machine

Embroidery-focused domestic machines allow downloading or creating embroidery designs and stitching them out automatically. Extras like multiple hoops, editing software, and an abundant design selection make DIY embroidery simpler. Some combo machines allow both standard and embroidery sewing.

Overlock or Serger Machine

Sergers, also known as overlock machines, create professional-looking finished seams and edges using 2–5 threads cut and stitched simultaneously. They work ideally for stretch fabrics, speedy seam finishing, and edging already-sewn material. Most home sewers use a standard machine paired with a separate serger for specialty finishing.

Coverstitch Machine

Coverstitch machines produce beautiful stretchy, reinforced hems ideal for activewear using multiple parallel rows of stitching across seam allowances. They create a smooth, flat hem, unlike standard double-needle stitching. Most home sewers can achieve similar results with a serger, but a dedicated Coverstitch gives maximum finishing.

This covers the key specialized domestic sewing machines tailored to techniques like quilting, embroidery, garment construction, and portability. Next, we’ll explore the heavy-duty industrial machine types designed for manufacturing environments and high-volume sewing.

Types of Sewing Machines (Industrial)

Industrial sewing machines represent the heavy-duty end of the spectrum, engineered for extended, high-speed production. Let’s overview some of the common types used in manufacturing settings.

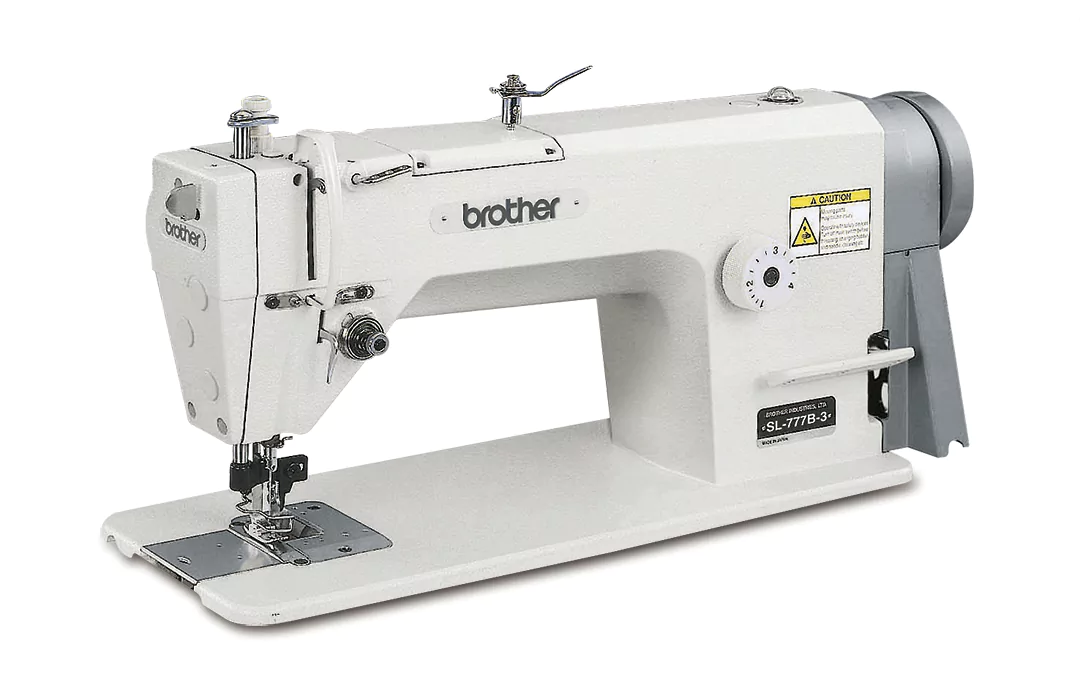

Straight Stitch Sewing Machine

As the name implies, Straight Stitch industrial machines focus on producing simple straight seams rapidly and accurately. Models made specifically for apparel construction often include a few common specialty stitches too, like zigzag or triple straight. Their high speeds, upwards of 5,000 stitches per minute, make them extremely efficient for mass production lines.

Industrial Serger Machine

Industrial sergers perform seam finishing and edging at blazing speeds. They trim and encase raw edges with stitching up to 9,000 stitches per minute. Heavy-duty knife blades and overlock loopers join and cut fabric in one motion. Sergers work ideally for factories finishing large quantities of layers in apparel and other products.

Coverstitch Industrial Machine

Coverstitch industrial machines create professional hems on the edges of activewear and stretchy fabrics. The two to four parallel rows of stitching seal the seam allowance with stretch and durability. High-speed over-edge Coverstitch machines allow maximum production volume of hems for leggings, swimwear, and performance wear manufacturing.

Chain Stitch Sewing Machine

Chain Stitch machines form stitches that interloop on the underside of fabric in a chain-like manner. This allows protective decorative stitching, gathering, or flexible seams, which are ideal for knits. Chain stitch is commonly used for items like t-shirts, upholstery piping, and blind hems that can unravel if the chain breaks.

Specialty Industrial Machines

Beyond the general industrial machines above, ultra-specialized models engineer niche manufacturing tasks:

Commercial embroidery machine

The industrial embroidery machine allows maximum production of embroidered designs for factories and decoration shops. Multiple hoops stitch out designs simultaneously for uninterrupted volume embroidery production. Networked capabilities manage complex multi-color designs and integrate them with digitizing software.

Safety stitch machines

They are vital for children’s clothing factories. Their unique stitch resists natural unraveling, even if the seam is cut or damaged. This prevents loose threads and holes from growing larger and compromising the garment over time. This safety stitch provides an extra layer of protection and reinforcement for the lifespan of children’s apparel.

Blind stitch machine

It creates nearly invisible hems by catching just a few threads of the fabric. The zigzag stitch remains hidden inside the fold. They produce undetectable hems on suits, formal wear, drapes, and high-end textiles where discreet hems are desired.

Flat Seam Machine

This Flar Seam industrial sewing machine makes sturdy, reinforced yet flat, and decorative seams ideal for prominently featured joints in high-end garments and upholstery. Coverstitch and chain stitch machines optimized for flat seaming control the tension and delivery of parallel rows of stitching for perfectly flat, finished layers that complement the design of textiles.

Bar tack machine

The Bar Tack Industrial machine forms densely packed zigzag stitches to reinforce points that experience high stress and strain. The condensed stitches prevent rips and holes from forming. Common bar tack applications include reinforcing pocket corners, belt loop ends, and any abrasion or stress points on items like jeans, leather goods, upholstery, luggage, and more.

Lockstitch Machines

A Lockstitch sewing machine makes super elastic stitches perfect for heavy-duty industrial fabrics like vinyl, leather, and upholstery. The unique knotting of the upper and lower threads interlocks the stitch, so it cannot easily be pulled loose or unraveled. This lockstitch method results in seams that withstand incredible tension and friction without breakage, making them ideal for heavyweight textiles.

Buttonhole Machine

The buttonhole sewing machine produces precise, reinforced buttonholes even on dense fabrics like denim. Their programmable stitch pattern, density, and enforcement result in professional, uniform buttonholes optimized for lifespan and functionality. Buttonhole industrial machines enable factories to efficiently create button closures on large quantities of jeans, overalls, jackets, and similar garments.

Button sewing machine

A button industrial machine automates the attachment of buttons to the fabric. This allows mass production of garments, upholstery, and other textiles requiring button closures. The machine precisely feeds and positions each button to be stitched in place rapidly and accurately. Some models include automatic button feeding mechanisms to maximize high-volume button sewing.

Leather sewing machine

The industrial leather machine includes special needles and walking feet specifically textured to grip slick leather tightly and sew without slippage. Adjustable feed mechanisms prevent thin leather from getting pushed and warped. Sturdy motors provide power to penetrate leather’s tough exterior. Together, these features allow sewing leather seamlessly without any skipped stitches, puckering, or distortion.

Types of Sewing Machines (Vintage)

Beyond modern domestic and industrial machines, a variety of antique and vintage machine types provide historical charm:

Toy Sewing Machine

Toy sewing machines offer a simple introduction to sewing for children. Mostly made of plastic, these miniature novelty machines often use pre-pierced paper or soft fabrics with pre-cut holes to simulate stitching. Highly portable and very user-friendly for developing dexterity and interest in sewing at a young age.

Manual/Hand Crank Sewing Machine

As the name suggests, manual or Hand Crank sewing machines operate completely mechanically without any electric power. Turning the hand crank manually powers the needle for basic straight stitching.

These vintage-inspired machines work well for beginners learning the basics without complex functions. The simple mechanics also make repair and maintenance more straightforward. Hand-crank portability allows sewing on-the-go. Limitations include only being able to sew thinner fabrics and requiring physical labor to operate the crank.

Treadle Sewing Machine

Treadle sewing machines contain a foot pedal that connects to a drive wheel that powers the needle motion. The sewer pumps the treadle up and down to move the needle at a comfortable pace. Treadle control allows speed adjustment. These vintage machines evoke nostalgia but require coordination and lack the conveniences of modern electric models.

Vintage portable sewing machines

Before miniaturization, early portable sewing machines still aimed for compactness to enable sewing on-the-go. Designs with sleek protective cases, fold-down bodies, and lightweight materials provide ease of travel. While bulkier than today’s machines, vintage portables represent ingenious steps toward mobility in an era before transistors and microchips.

Vintage Zigzag Models

As household electricity became widespread in the early-to-mid 1900s, the first mainstream electronic sewing machines emerged. These featured electric motors for easier operation and innovative zigzag stitches for versatility. Vintage zigzag models represent a transition point between purely mechanical and today’s computerized machines.

This covers some of the key vintage and historical sewing machines that preceded modern advancements. Understanding where sewing technology originated provides an enlightening perspective on how far it has progressed.

Conclusion in – Types of Sewing Machines

We’ve covered a wide variety of types of sewing machines, ranging from vintage antiques to cutting-edge computerized models. Understanding the strengths and limitations of the main categories of domestic, industrial, and vintage machines enables you to select the optimal machine for your sewing skills and projects.

With this knowledge of the various sewing machine types available, you can confidently choose the right machine that aligns with your skills, interests, and projects. For more details on specific models, brands, and buying considerations, check out our related in-depth sewing machine buying guide. Happy sewing!

Excellent pieces. Keep posting such kind of information on your page.

Im realply impressed by your blog.

Hi there, Yoou have done a great job. I’ll definitely digg it and in my view suggest to my friends.

I’m sure they will be benefited from this site.